"Customers who challenge us"

GEALAN has 2022 its premium system GEALAN-KONTUR®. It combines design-oriented Design language with convincing Technical Characteristics. Its development was a joint project between the system provider and two window manufacturers: Felbermayer and PaX. Robert Tänzel (45), Sales Head of Division at GEALAN, has talked to us with the two project partners. He tells of a challenging all sides Cooperation. And of other challenges he has tackled – long before he has joined GEALAN.

On the afternoon of August 31, 2002 in the catacombs of the Hindenburg Stadium in Ihrhove, East Frisia: The players of SV Concordia have gathered in their dressing room. They have the first half of the game of their lives behind them. The club from the fourth-tier Oberliga Niedersachsen/ Bremen is in the first round of the DFB Cup and challenges none other than the reigning German football champions to a David vs. Goliath duel: 15,000 spectators watch Concordia Ihrhove against Borussia Dortmund. "I sat in the dressing room and said: I want to win!" recalls Robert Tänzel, who had just moved to Ihrhove as a 22-year-old midfielder. "We didn't have a bad team and you just have to believe that we can hold our own against the German champions." The score is 0-0 at half-time. The amateurs are holding up well, losing, but the 3-0 defeat against the mighty BVB is respectable. "It was a great experience, but: Challenge missed. The bulb is empty. You've lost the competition." Tänzel's head quickly fills up again – with ideas for the game, with ideas for the future. He will face further challenges, in football and later at GEALAN.

Robert Tänzel at the architecturally spectacular Liège-Guillemins station; when travelling to GEALAN customers in the Benelux, he often changed trains here. For him, customer visits are much more than sales talks – it's about exchange, understanding and practical relevance: "We don't build windows. We develop profiles. Feedback from processors is essential for us."

Challenge 1: Dribbling with follow-up action

Robert Tänzel, born in Nuremberg in 1980, dashes across the pitch of Zabo Eintracht Nürnberg, the youth club of football world champion Max Morlock, as a five-year-old toddler. In the D-Youth, he scores 100 goals in a season, but is also in goal from time to time. At 15, he went to Greuther Fürth. Via Ihrhove, Spain and Switzerland, football took him to the fifth division in the summer of 2004 to FC Bayern Hof, where GEALAN is the jersey sponsor. "In the second year it worked out with promotion, but there was unrest in the club and the coach I had come for had to go. Somehow it was slowly enough with football. So I set my focus completely differently."

In 2005, while still an active footballer, Tänzel began a dual course of study in business administration with an apprenticeship as an industrial clerk at GEALAN. As a newcomer, he gets a special assignment: "I have weeks in a GEANOVA. THE NEW GEALAN | 14 discarded sea containers, which served as an archive. I was given 100 boxes of files, which I sorted and neatly put on shelves." In the internal sales department, Robert Tänzel enjoys talking to customers on the phone. He did not fall for his mouth, his training manager attests to him. GEALAN Managing Director Ivica Maurović also recognises Robert Tänzel's propensity to sell. The two are in regular exchange for Tänzel's diploma thesis, which he wrote in 2011. In it, he develops an Internet communication strategy for GEALAN marketing. Robert Tänzel becomes assistant to the sales manager for eastern Germany, then assistant to the sales manager for D/A/CH and Benelux and quickly promoted to country representative Benelux. "I had a lot of creative freedom, was often with customers and tried to win new customers. That worked quite well – we have tripled our Benelux turnover since then." In 2012, Maurović made Tänzel Head of Sales for Benelux, the Czech Republic and Slovakia. In 2018, he was granted power of attorney and became Head of Sales Area 1, which includes Germany, Austria, Switzerland, Benelux and Slovenia.

After the sporting challenge in football, Robert Tänzel accepted the professional challenge at GEALAN. "As an apprentice, you look around, crawl through the sea container and think to yourself, aha, so this is professional life. Even as an assistant, I felt trust, was allowed to do a lot and wanted to create something. Benelux was just the right thing for me – and the next challenge: new countries, customers with their own requirements."

Challenge 2: Implement food for thought

An open ear for the needs of customers and a clear view of market and design trends – this is how GEALAN's sales department contributes to the development of new products. Years pass from the idea to the market launch. For a profile system to be successful, all players must provide the right answers – first to basic and later to detailed questions: Should the new system expand the product range or replace an old one? For which countries is it relevant? How does it achieve the best values for thermal insulation, sound insulation and burglary protection? How can the profiles be optimally processed into windows? Product management is in charge of coordinating the complex process. Design, toolmaking, architectural consulting, construction technology, application technology, test centres, marketing – many wheels interlock. In addition to the in-house expert know-how, the expertise of those for whom GEALAN develops products is indispensable: the profile processors. When the first thoughts revolved around GEALAN-KONTUR® in 2019, two idea generators were already on board, whose wishes Robert Tänzel knows from sales practice – "customers who challenge us", as he says: "The PaX specification was a system with a fixed centre seal dome for burglary protection in the premium segment. For Felbermayer, the new system had to be perfectly processable – fully automated, from the threshold to the aluminium shell."

Challenge 3: Enable automation

In 1993, Helmut Felbermayer (59) took over the small carpentry shop that his father had founded in 1963. After several changes of location, Felbermayer Fenster und Türen Erzeugungs- GmbH has been based in Unterwaltersdorf, Lower Austria, about 30 kilometers south of Vienna, since 2012. It has around 200 employees – 160 in production and 40 in administration and on construction sites. On 32,000 square metres, it manufactures wooden windows, wood-aluminium windows, PVC and PVC-aluminium windows. "I come from wood, I'm a master carpenter," says Helmut Felbermayer. "But now I see myself as an entrepreneur and no longer have a moral problem with plastic windows. We have to be powerful with both materials. Ten years ago, plastic dominated, now more wood-aluminium is possible, but we are currently seeing a trend reversal back to plastic in terms of offerings." Felbermayer brings a lot of expertise in-house, cuts aluminium shells he has developed himself, operates an internal insulating glass plant and powder coating, is currently setting up a production facility for solid aluminium elements and generating electricity. "Outsourcing was on everyone's lips. And when Corona came, you could see that it was the wrong thing. Because we do a lot ourselves, the pandemic and the interrupted supply chains have not hit us so hard. Of course, this independence and flexibility requires large material inventories that have to be pre-financed."

Big is beautiful: Felbermayer usually handles orders with a volume of several hundred thousand euros. In Vienna and Austria's major cities, the property construction specialist equips residential, high-rise, office and functional buildings such as hospitals with windows and doors. "It's the assembly that makes the difference. This is how you give the business card for the next construction site. And of course, you have to deliver on time. Sounds like stress, but I don't know that word."

Felbermayer's entry into the plastic window business in 2013 was frustrating: Purchased ready-made windows caused trouble and after just a few projects it was clear: "Either we stop using plastic again or we do something of our own!" An employee establishes contact with GEALAN. Helmut Felbermayer is enthusiastic about STV® adhesive technology, but "I quickly realised that the only way to do this is to have your own profile. The profiles on the market were pretty, but simply not suitable for our requirements in commercial construction. Felbermayer draws an angular window system with a central seal dome and all the features and details that are important to him: large-dimensioned steel bracing is intended to counteract torsion, maximise statics and allow the construction of higher elements. For the uncomplicated, tight connection of sashes with speed bumps, he is planning special screw channels, as well as chambers for the additional screwing of heavy fittings. As a mounting option for aluminium cladding, he would like to see clip connections on the outside of the profile. His sketch is incorporated into the development of GEALAN-KONTUR®. "I tried to set up a system that guarantees perfect statics for large elements with strong insulating glass. GEALAN has succeeded in implementing this. We hardly have to readjust windows anymore."

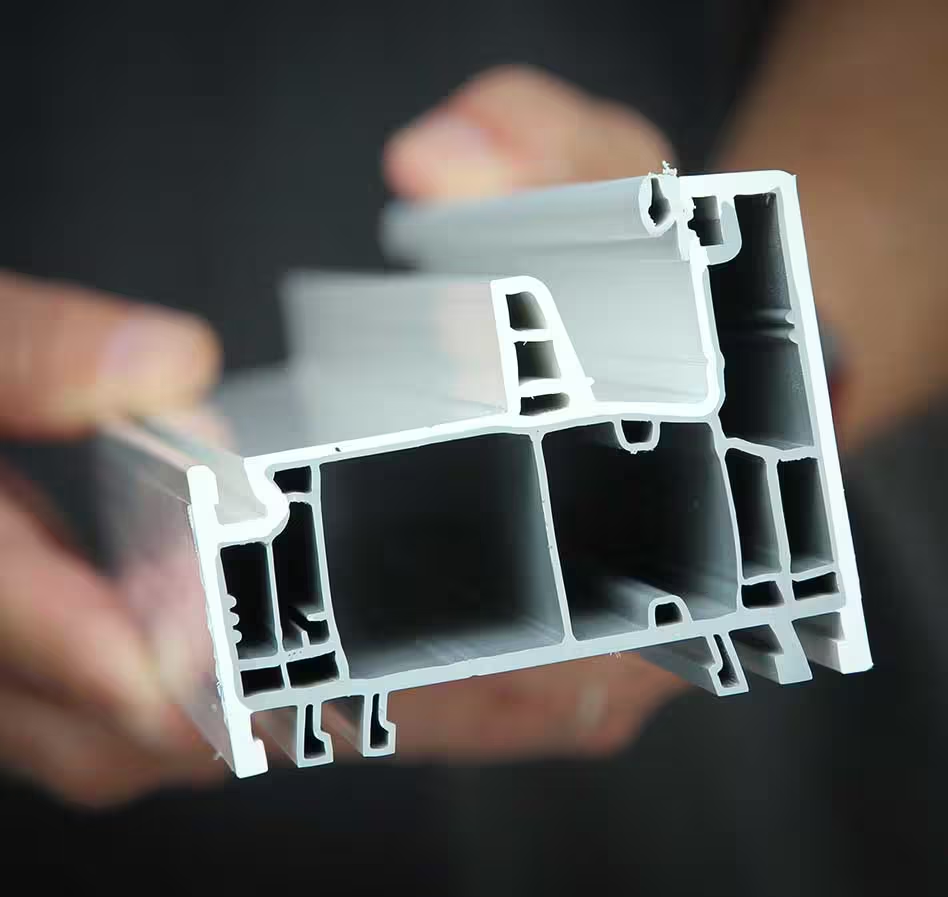

GEALAN-KONTUR® combines the trend towards angular profiles with an installation depth of 82.5 millimetres. As a center seal system, it has a fixed web and three closing seals. Large steel reinforcements fit closely to the PVC, so that even large elements remain stable. GEALAN has integrated screw channels for a secure sleeper connection. GEALANKONTUR ® is broadly positioned – with various sashes, frames and posts, all in GEALAN-acrylcolor®. The system is suitable for all types of glazing: classic blocking, wet bonding and bonding with STV® (static-dry-glazing).

Working profitably is essential. Helmut Felbermayer makes no secret of this. He questions work steps and invests in the automation of his production lines. "We don't automate with a crowbar, but we have gained an advantage over competitors who manufacture windows with more labor-intensive requirements. A plastic window can now be built at a gigantic speed. If you chat a bit, it will overtake you. GEALAN supplies us with thresholds that we can attach very quickly and tightly thanks to the screw channels in the profile. Elsewhere this is a case for special construction, but here it is standard." GEALAN-KONTUR® enables the automatic release of the frame for the outer and inner construction connection. Its central seal in the sash is suitable for mechanical feeding. It has a flat sash rebate for wet bonding automation and a flat frame rebate for fixed glazing automation.

Pictures above: The mounting clips for aluminium cladding are attached to the GEALAN CONTOUR® profile fully automatically. Picture below: During the Corona pandemic, Felbermayer set up an in-house insulating glass plant.

Challenge 4: Meet security standards

Andreas Kohl (61) introduces himself as a "trained electrician and aborted mathematics student with an eventful life." He worked in the wholesale trade for spectacle frames and at the post office before joining PaX in 1995. There he starts as a clerk in sales and marketing, becomes product manager for burglary resistance, then sales manager. Once he has merged the systems and products of all PaX locations into one ERP system, he takes over responsibility for the entire product range and ultimately for the entire operational operation. In 2014, he joined the Executive Board; since the death of the company's founder, Dr. Fritz Struth, he has been the sole member of the Management Board.

PaX – the name introduced in the nineties is derived from the Latin word for peace. Windows protect houses and their inhabitants from external influences and maintain peace in the house. "Security is a basic need," says Andreas Kohl. "But burglary protection is not standard in window construction. The standard only seriously defines safety from Resistance Class 2 onwards. However, we still derive two levels below the norm for our range – quite deliberately, for cost reasons. On the first floor, attack-resistant glass is not absolutely necessary, but reasonable basic protection makes sense. You can achieve a lot with relatively little effort and use of materials. That's how we differentiate ourselves."

The so-called People's Security Window is an early PaX creation from 1993 – a burglar-resistant window, available almost at no extra charge. It lays the foundation for the certified PaXsecura product range – one of the unique selling points devised by Dr. Fritz Struth. In 1984, his family took over Fensterbau Schweikhard in Ingelheim am Rhein, which had emerged from a wheelwright's shop. The Oxford graduate is supposed to get the ailing company back on track. He turns Schweikhard into PaX, transforms the regional direct marketer into a supra-regional window manufacturer with its own dealer network. Far before others, he had windows manufactured on an assembly line and developed universal components, such as locking parts that could be installed on the left or right. Struth is a visionary who is driving automation and digitalization. "He wanted to get rid of all the pieces of paper and started programming himself on a Linux basis in the early nineties. He has networked all our locations with each other." PaX produces in Rositz (Thuringia), Vestenbergsgreuth (Middle Franconia), Hermeskeil (Rhineland-Palatinate) and Bad Lausick (Saxony). Kohl describes PaX as a full-range supplier with a high degree of integration. And the product portfolio confirms this: GEANOVA. THE NEW GEALAN | 18 wood and wood-aluminium windows, PVC-PVC, PVC-aluminium and aluminium windows, PaXscura security windows, front doors made of wood, wood-aluminium, aluminium and PVC, the PaXclassic monument protection line, roller shutters, insect screens.

Shortly before the turn of the millennium, the paths of PaX and GEALAN cross for the first time. The profile manufacturer is currently designing a new system, and the USP-driven Dr. Struth is preaching to the public with his ideas. He activated his contacts at the Bauhaus University in Weimar and gained valuable insights into the U-value calculation. "The S 7000 system, which he developed with GEALAN, was only 10 percent away from the theoretical U-value maximum at an installation depth of 74 millimetres. And the maximum is practically unattainable." For burglary resistance, the S 7000 is fitted with a fixed centre seal stop. "The system was so good that it ran for 25 years." PaX generates more than half of its sales with the successful system.

When GEALAN wanted to take the aging S 7000 out of the range in 2019, PaX was back at the table. For the second time, the two are jointly developing a profile system – GEALAN-KONTUR.® PaX brings two core requirements: the established fixed center seal stop and higher material use in the right places to make the profile stiffer and better withstand mechanical attacks. "Steels that fit closely to the plastic were also important to us. In empty spaces, the lever can apply better and act with greater force. Tight tolerances bring stability to the system." Of course, GEALAN cannot tailor its own profile system for everyone. "That can't be the goal either," says Andreas Kohl. "Before GEALAN, we had our own systems. Tools are extremely expensive, certifications are time-consuming and further development is difficult if you as an individual only need relatively small quantities. A system must meet the needs of as many processors as possible."

Challenge 5: Success in the market

Well-founded input from two window manufacturers who know what they want and what they need and a system provider who perceives wishes and creates innovations. The new development of GEALAN-KONTUR® was a challenge for all project partners. "Trust is the prerequisite," says Andreas Kohl. We put all our eggs in one basket, everything in a new system. Of course, this must not go wrong. And GEALAN has invested millions. You have to know each other for a while to take such a step together." Challenge mastered: GEALAN-KONTUR® is on the market. But in highly competitive markets, the next challenges are already waiting. "If your business is developing badly or a customer drops out, you've lost," says Robert Tänzel. "If your customers perform better than others and you win new customers with new products, you're a winner. GEALAN-KONTUR® is a top product with which we really differentiate ourselves. Our customers benefit from real distinguishing features in the upper segment. GEALAN confirms what I have learned in sport: nothing comes from nothing."

Attempted burglary with screwdriver and wooden wedge: For about twenty minutes, Sven Ruppenthal from the PaX team makes every effort to open a window by force. But the element, which is made of GEALAN CONTOUR profiles®, withstands the attack.

Götz Gemeinhardt

13/11/2025

Latest articles

GEALAN from the inside

GEALAN from the inside

A really good tool for internal communication: GEALAN inside is anything but a bulletin board; the digital platform is a prime example of how internal company information can be bundled and prepared in a user-friendly way. GEALAN inside is packed with interesting facts and yet clear, offers umpteen functions and is easy to use. All those who work at GEALAN have their virtual meeting place – and on top of that, GEALAN inside looks chic too.

Through the eyes of a physicist

Through the eyes of a physicist

Cameras on, high quality: The optical control systems, GEALAN on the extrusion lines in Tanna, are a direct investment in quality. You will work with Artificial Intelligence and recognize on the profile surfaces almost every Deviation from the optimum. A droplet of water on the profile? No problem. A visible scratch or tiny bubble? Immediately used as Error reported – and that in extrusion speed, such decisions for the human eye almost impossible. Dr.-Ing. Winfried Bernhard (55), Head of GEALAN Quality Management and the man who GEALAN's quality offensive, looks at the new hardware, and nods. Nor are they a test, but how good the systems work and how closely they look, already fascinates him.

99 percent is not enough

99 percent is not enough

Trucks roll along highways and transport goods from A to B. A symbol of logistics. This is not a false picture, but an incomplete one. The German Logistics Association (BVL) defines logistics as the holistic planning, management, coordination, implementation and control of all internal company processes. and cross-company flows of information and goods. Sounds complex and it is. GEALAN is making its logistics more and more efficient, thus pursuing one goal: maximum delivery reliability.