Back to square one - from production to IT department

Mohammad Kamandar is new to the GEALAN IT department. Until October 2021, he was still working in production in Tanna. The new colleague has come full circle after his successful internal reapplication, as the Iranian had already worked as a computer scientist in his home country for many years.

Software, hardware, cloud systems, automation: all these things are not unknown to Mohammad Kamandar, who, after studying computer science in Iran, was employed for ten years as an IT specialist with the police. "The tasks and systems were different there, however," he says, describing why a training period with the GEALAN experts was urgently needed. "In addition, I don't speak German that well yet - but I want to learn it as soon as possible, have already taken private online language courses, and am currently completing one that GEALAN made possible for me."

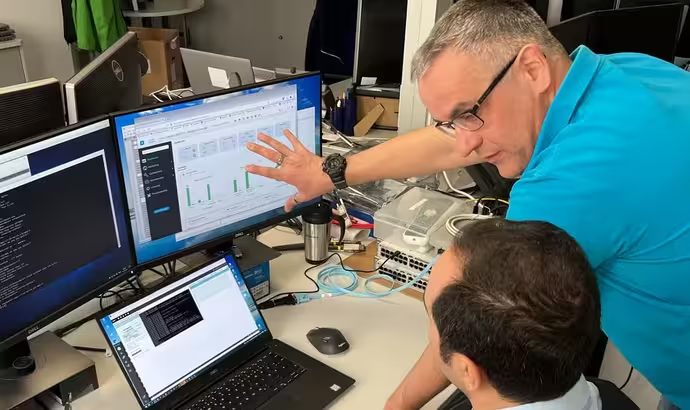

Mohammad Kamandar fled Iran about three years ago. The fact that after his long journey, face-to-face language courses were hardly possible in Corona times was the least of his problems at the time. "I came to Germany via Turkey and Greece, started from scratch here," he explains. The job at the extrusion in Tanna is his first in Germany, and he will be employed there for five months from May 2021. When his Iranian papers are certified, he presents GEALAN with the recognised documents, including IT training. A win-win situation opens up: "We were looking for someone to assist us in IT support in Tanna," explains André Spranger, his supervisor at GEALAN, "and Mr Kamandar offered his expertise. Besides, he himself also wanted to return to his actual area of responsibility." The plan is for Mohammad Kamandar to look after the industrial IT at the site, which means, for example, fixing IT problems on production equipment, maintaining computers, monitors and printing solutions installed on machines. Andre Spranger: "Our goal is for him to know independently what needs to be done and to be able to take care of it if, for example, the laminating department reports an IT problem."

Mohammad Kamandar is currently working two days a week in Tanna and three days in Oberkotzau. The training makes this necessary (for the time being). Sooner or later, he will work four days in Tanna, where technical problems cannot usually be solved remotely. He will then spend only one day with the rest of the IT team: "He should be where he is needed as often as possible, but still not lose touch with the team," says André Spranger, describing the intended model.

Mohammad Kamandar is happy to be able to contribute his skills at GEALAN: "Working in production was new to me, I had to learn everything from scratch. Working with computers, software and networks is what I can and want to do." The familiarisation with the new job is bearing fruit; little by little, Mohammad Kamandar is acquiring what he needs for his daily work, so that he will soon be able to help his colleagues in Tanna run smoothly on their own. "He is very interested and gets involved," the supervisor praises the new colleague's commitment. "He deserves the chance to develop here. And he can also contribute his skills even better for the good of GEALAN."

Marc Schenk

17/08/2022

Latest articles

GEALAN from the inside

GEALAN from the inside

A really good tool for internal communication: GEALAN inside is anything but a bulletin board; the digital platform is a prime example of how internal company information can be bundled and prepared in a user-friendly way. GEALAN inside is packed with interesting facts and yet clear, offers umpteen functions and is easy to use. All those who work at GEALAN have their virtual meeting place – and on top of that, GEALAN inside looks chic too.

"Customers who challenge us"

"Customers who challenge us"

GEALAN has 2022 its premium system GEALAN-KONTUR®. It combines design-oriented Design language with convincing Technical Characteristics. Its development was a joint project between the system provider and two window manufacturers: Felbermayer and PaX. Robert Tänzel (45), Sales Head of Division at GEALAN, has talked to us with the two project partners. He tells of a challenging all sides Cooperation. And of other challenges he has tackled – long before he has joined GEALAN.

Through the eyes of a physicist

Through the eyes of a physicist

Cameras on, high quality: The optical control systems, GEALAN on the extrusion lines in Tanna, are a direct investment in quality. You will work with Artificial Intelligence and recognize on the profile surfaces almost every Deviation from the optimum. A droplet of water on the profile? No problem. A visible scratch or tiny bubble? Immediately used as Error reported – and that in extrusion speed, such decisions for the human eye almost impossible. Dr.-Ing. Winfried Bernhard (55), Head of GEALAN Quality Management and the man who GEALAN's quality offensive, looks at the new hardware, and nods. Nor are they a test, but how good the systems work and how closely they look, already fascinates him.