99 percent is not enough

Thomas Heinz is satisfied: In the order change pilot phase, the picking of eight containers according to customer requirements went smoothly.

Trucks roll along highways and transport goods from A to B. A symbol of logistics. This is not a false picture, but an incomplete one. The German Logistics Association (BVL) defines logistics as the holistic planning, management, coordination, implementation and control of all internal company processes. and cross-company flows of information and goods. Sounds complex and it is. GEALAN is making its logistics more and more efficient, thus pursuing one goal: maximum delivery reliability.

Always at the end of the year, Beatrix Ludwig (27) looks to the future. Not with a crystal ball, but by evaluating data. It prepares the annual plan for GEALAN's profile production in Tanna, which is based on strategic corporate goals. It defines planned quantities that are to be extruded in the following year. It simulates how inventories develop and how storage capacities are utilized. Beatrix Ludwig is not a clairvoyant. She is a specialist in strategic logistics. "There is a wide range between long-term planning and operational planning for the coming working week. The annual plan is a rough plan, which is of course adjusted monthly. In operational planning, which I support in an advisory capacity, it is specifically determined which order is to be implemented on which system." Within GEALAN logistics, production planning acts as a link between production and the warehouse where deliveries are picked.

Beatrix Ludwig worked at GEALAN as an intern and working student. She studied supply chain management and logistics at Hof University of Applied Sciences. She already wrote her master's thesis in cooperation with GEALAN, in which she dealt with production planning with the help of SAP. She has been a permanent employee at GEALAN since 2022 and puts her theoretical knowledge into practice: "I wanted to create transparency between long-term and short-term capacity planning. If work planners have access to statistical evaluations and forecasts, they can use free capacities to pre-produce. In this way, they ensure that GEALAN remains able to deliver even in foreseeable peaks in demand. I can now implement the concept from my master's thesis step by step." Software evaluates past consumption at GEALAN, derives consumption patterns from this and calculates forecasts using various methods. But strategic logistics does not rely on these predictions alone. It constantly questions whether it can make better use of production, but also takes care to avoid overloading. "We have a lot of data in our systems," says Beatrix Ludwig. Gaining access to them, evaluating them, visualizing them – that is a challenge. GEALAN feeds its data to a process mining tool from Celonis. The program analyzes the input. "We get the big picture because Celonis allows us to tap into multiple data sources. We gain insights that our production can really do something with, because it can see at a glance where action needs to be taken."

One of GEALAN's internal data suppliers is Thomas Heinz (44). He explains: "Data is endless. It is important to structure them. When you install Celonis, nothing happens at first. Users have to define which processes they want to analyze, what they want to see. Celonis needs to be brought to life. And that's exactly what GEALAN does." Thomas Heinz summarizes his curriculum vitae in a nutshell: business school, Bundeswehr, GEALAN. He started in logistics in 2002, dealing with material flow control and advising customers on logistics. Six years ago, he switched to IT. As Head of Application Consulting, he coordinates an eight-person group that specialises, among other things, in connecting customers to Enterprise Resource Planning (ERP), the warehouse management system (LFS) and the further development of GEALAN's e-commerce.

Celonis merges several databases from the SAP business software and the warehouse management system and is thus able to map a complete process. Celonis conducts data mining, i.e. extracts from a large amount of data in which patterns, relationships and trends can be discovered. GEALAN prepares this data for subsequent processes. "The customer order throughput is an integrated process in which several internal systems are involved," says Thomas Heinz. "The customer's order is recorded in SAP. Material Requirements Planning generates a planned order or purchase requisition from SAP for later implementation. The appointment chain holds everything together. Time stamps and production documents document the flow of the customer order."

The wealth of data generated during the order-to-cash process is interesting for logistics. They lay the foundation for two use cases, which Beatrix Ludwig cites: "The production planner can compare article stocks with customer orders and delivery dates. If he detects a potential shortfall in demand, he can take countermeasures to avoid a drop in inventory on the delivery date." Without Celonis, the planner would have to laboriously call up the current stock of each individual item and speculate whether the stock could slip into the red. "And the warehouse uses Celonis as a basis for planning. The planners learn at an early stage what needs to be picked and loaded for which customer and when. They know how many staff they have to deploy and what picking effort they will have to do."

Process handling continues to take place in the ERP and in the merchandise management system. GEALAN has so far used Celonis purely as a visualization tool. Its strengths are monitoring, the consolidation of information and process mining. Thomas Heinz: "The software also shows us where the standardized order-to-cash process has stalled in the past. We analyze where things have hitched, can make adjustments and thus optimize our process. This is a very strong use case." In logistics, the value of condensed information is obvious, because data from many networked systems is collected here. Beatrix Ludwig also takes part in cross-departmental workshops: "In them, we shed light on the entire customer order process."

Internally optimized processes have a positive external effect because customers benefit from maximized delivery reliability. Another logistics project by GEALAN even enables customers to intervene directly in the action and influence the delivery of ordered goods. The next level of interaction between customers and system providers is called "Order Change". With Order Change, GEALAN is fulfilling two customer requirements: firstly, delivery dates can be postponed into the future, and secondly, profiles are sorted into transport containers in such a way that the profile required first by the processor can also be removed first.

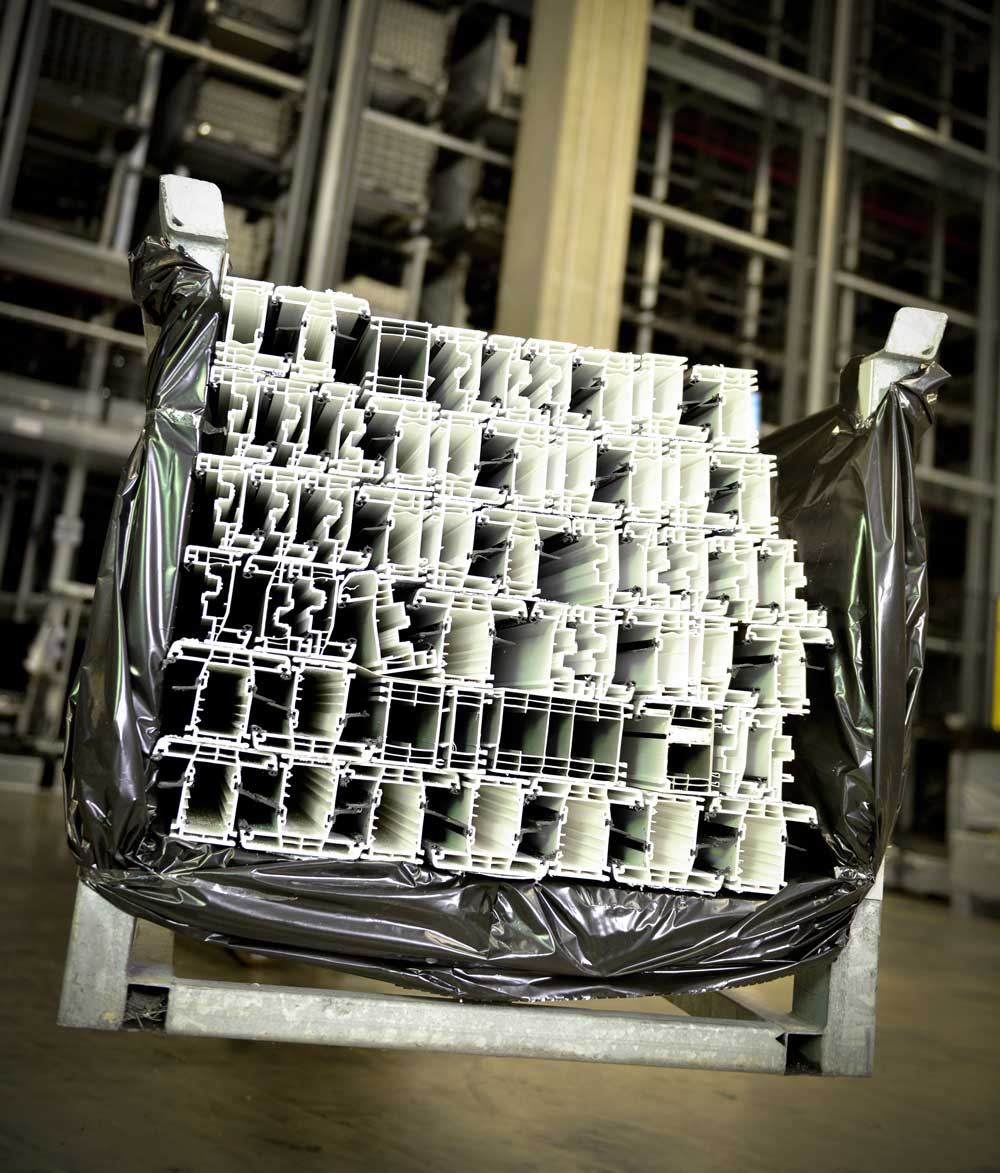

Packed as ordered, order change makes it possible: The customer's production planning specifies the order in which GEALAN places profile bars in containers. Profiles that the customer wants to process first are at the top.

Push delivery dates into the future? This seems paradoxical, because customers usually want to be supplied as quickly as possible. However, a delivery can be unusable for a window manufacturer for the time being if it is not complete. Complete construction projects can only be realised with complete deliveries. One week before the planned delivery date, GEALAN sends the recipient an ASN. This shipping note lists all items that can be sent on the near delivery date. "A missing pole can be the decisive pole," says Thomas Heinz. "If an order consists of ten items and we only deliver nine, the customer lacks profiles that he needs to be able to fulfill an order himself. And before he puts nine out of ten items in stock, he prefers to postpone the delivery date and receive all ten items at once a little later." Complete deliveries not only benefit the customer: partial and subsequent deliveries mean more logistical effort, higher transport costs, and a higher burden on the environment and infrastructure.

The statistics show a delivery reliability of 99 percent for GEALAN. This means that 99 out of 100 items ordered are delivered on time. At first glance, this is fantastic value, but "our customers don't think in positions – they think project-related. The one missing percent can have a huge impact on profile processing. We always want to get better and give the customer what he needs: transparency, communication and planning security. Delivery postponements are often not a problem at all if customers can react to them. With Order Change, we are giving them the tool to do so."

The ASN also lays the foundation for the second use case of Order Change, as it is the basis for the customer's concrete production planning. He übertr.gt the data from his planning to GEALAN via order change. "We use it to generate a string, an alphanumeric code that adjusts the order of the picking list in the merchandise management system," says Thomas Heinz. There is room for 60 profile bars in a transport container. The customer can theoretically assign an item to each of these 60 defined items. In practice, the data from his production planning determines how the container is to be filled. "In the past, we sorted by item type within a container: profiles for frames, then for sashes, and so on. Customers had to tear open the containers and laboriously pick out what they needed at the time." Profiles picked according to production sequence – that brings real added value. GEALAN installed the ASN, set up interfaces and adapted its data structure. Order Change is currently undergoing a pilot phase, in cooperation with HÖNING GmbH. HÖNING helped initiate the project, formulated requirements for order change and made many internal adjustments itself. Thomas Heinz is proud: "We offer a service that no other system provider has." A service that makes order picking at GEALAN more detailed and therefore more complex. A service that requires efficient logistics. Since the completion of its high-bay warehouse in 2023, GEALAN has been picking much more efficiently in Tanna. Beatrix Ludwig summarizes the progress in figures: "In the high-bay warehouse, we achieve 11 picks per person-hour, twice the average value of the other storage areas. GEALAN defines a delivery note item as a pick – this can be a single profile bar or dozens. Together, the high-bay workforce can manage 40 to 50 picks per hour." The goal is 60 to 70 picks. This would mean that the high-bay warehouse would realize about 70 percent of all sales picks at the Tanna site. Thomas Heinz: "We are preparing a software exchange for even better high-bay performance. The new software improves the entire logic, so we will achieve more withdrawals per movement." The reliability is already bombastic. The warehouse management now has to learn to look into the future, for example not to transport a container that will soon be needed again to its distant regular place, but to park it sensibly temporarily.

The future of logistics – if you want to shape it, you have to know what customers have on their minds, says Beatrix Ludwig. "If we listen properly to our customers, we will find out which optimization we should put energy into. We plan to create a position for logistics customer consulting." Thomas Heinz is preparing to introduce a new cloud-based version of the LFS warehouse management system with new functions in Croatia in 2026. "Gradually, all locations of the GEALAN Group are to take over LFS V9," he says. "A uniform software solution will connect us even more closely internationally and further increase efficiency." With Celonis and Order Change, GEALAN has delivered. Trucks roll along highways from A to B, while GEALAN's journey continues on the information highway.

Götz Gemeinhardt

25/11/2025

Latest articles

GEALAN from the inside

GEALAN from the inside

A really good tool for internal communication: GEALAN inside is anything but a bulletin board; the digital platform is a prime example of how internal company information can be bundled and prepared in a user-friendly way. GEALAN inside is packed with interesting facts and yet clear, offers umpteen functions and is easy to use. All those who work at GEALAN have their virtual meeting place – and on top of that, GEALAN inside looks chic too.

"Customers who challenge us"

"Customers who challenge us"

GEALAN has 2022 its premium system GEALAN-KONTUR®. It combines design-oriented Design language with convincing Technical Characteristics. Its development was a joint project between the system provider and two window manufacturers: Felbermayer and PaX. Robert Tänzel (45), Sales Head of Division at GEALAN, has talked to us with the two project partners. He tells of a challenging all sides Cooperation. And of other challenges he has tackled – long before he has joined GEALAN.

Through the eyes of a physicist

Through the eyes of a physicist

Cameras on, high quality: The optical control systems, GEALAN on the extrusion lines in Tanna, are a direct investment in quality. You will work with Artificial Intelligence and recognize on the profile surfaces almost every Deviation from the optimum. A droplet of water on the profile? No problem. A visible scratch or tiny bubble? Immediately used as Error reported – and that in extrusion speed, such decisions for the human eye almost impossible. Dr.-Ing. Winfried Bernhard (55), Head of GEALAN Quality Management and the man who GEALAN's quality offensive, looks at the new hardware, and nods. Nor are they a test, but how good the systems work and how closely they look, already fascinates him.

Contact us, we will be happy to help you.

Do not miss any news!

I want to receive newsletter "Reference Building of the Month" and GEALAN news via E-Mail (approx. twice a month) - free of charge and terminable at any time.