IKD®

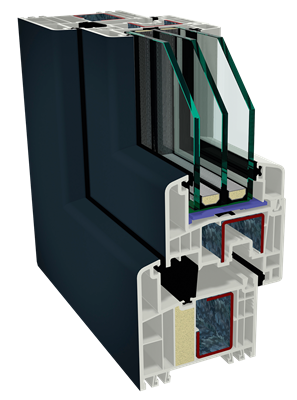

Intensive core insulation

Benefits for window construction

Reduced workload

Outstanding heat insulation no longer requires fitting the profiles with inserts by hand. The profiles are supplied pre-filled with foam.

No additional investment

The foam is injected into the profile chamber in the extrusion plant. The window manufacturer then receives the finished foam-filled profile off the shelf.

Easy recycling

The foam is kept in place inside the profile by pressure and not surface bonding. When the window sections are cut into pieces, the foam falls out of the profile and can be recycled separately.

Increased heat insulation

Sash profiles with IKD® technology can achieve Uf values of < 0.89 W/(m²K) when used in combination with STV® static dry glazing.

No steel stiffening elements

When used together with STV® technology, standard element sizes do not need steel stiffening elements. This saves weight, reduces transportation costs and makes installation easier.

Normal production process

The profiles can be cut, heat sealed and finished as normal.

Windows in a class of their own

IKD®: GEALAN's pioneering role

GEALAN is a pioneer in factory foam filling of profiles and launched the first foam-filled window and accessory profiles back in 2010.

Knowledge born of experience

Today GEALAN has a wealth of expertise in how to incorporate this technology into profile production.

Further benefits

- The profiles are foam-filled in the factory for GEALAN customers.

- No additional investment is required on the part of the fabricator.

- No changes required to the customer's production process.

- IKD® profiles can be recycled.

Systematic use

For the first time, GEALAN's IKD® intensive core insulation offers window manufacturers an efficient and economic way of producing windows that satisfy the highest demands in terms of heat insulation.

AN IMPRESSIVE PRODUCTION SEQUENCE

The window manufacturer then receives the finished foam-filled profile off the shelf. Watch our film about window production with IKD®.

Use our manufacturer locator.

Do not miss any news!

I want to receive newsletter "Reference Building of the Month" and GEALAN news via E-Mail (approx. twice a month) - free of charge and terminable at any time.