Through the eyes of a physicist

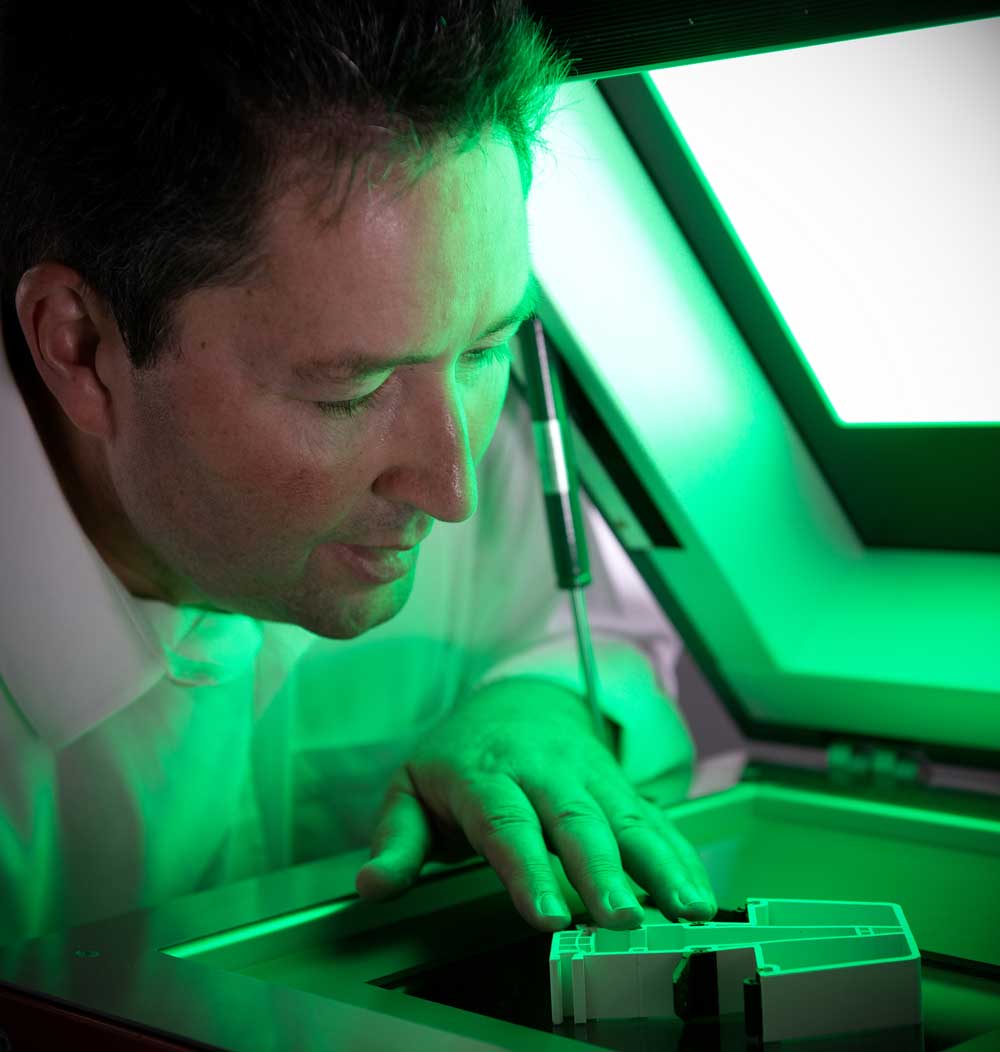

Cameras on, high quality: The optical control systems, GEALAN on the extrusion lines in Tanna, are a direct investment in quality. You will work with Artificial Intelligence and recognize on the profile surfaces almost every Deviation from the optimum. A droplet of water on the profile? No problem. A visible scratch or tiny bubble? Immediately used as Error reported – and that in extrusion speed, such decisions for the human eye almost impossible. Dr.-Ing. Winfried Bernhard (55), Head of GEALAN Quality Management and the man who GEALAN's quality offensive, looks at the new hardware, and nods. Nor are they a test, but how good the systems work and how closely they look, already fascinates him.

The precise view is something that Winfried Bernhard likes. Born in Ilmenau, he showed an extraordinary interest in natural sciences even as a child. His curiosity to understand nature and its laws caught the eye of his teachers. He attends a special class for technology, mathematics and natural sciences. Of all the scientific disciplines, he chose physics when studying – not because he thought it would give him the best career opportunities, but because he was enthusiastic about the subject itself – the fundamental, the comprehensive. Getting to the bottom of things and contexts and going into depth is an urge that will shape him and his entire professional life.

Quality requires an eye for detail. As Head of Quality, Dr. Winfried Bernhard is leading GEALAN's quality offensive. The aim is to work flawlessly – from purchasing to production to logistics. "We look at all processes and look for ways to improve. Optimal processes mean optimal quality."

During his studies in Jena, Winfried Bernhard worked for the Fraunhofer Institute. In his diploma thesis, he developed distributors for optical communication – fiber optic components that are still important today. "I never intended to become a theoretical physicist who sits in a quiet room. I always wanted practical relevance." A cooperation project brought him into contact with the industrial giant Bosch, which brought him to Stuttgart to join its research department. He is doing his doctorate parallel to his professional commitment. At Bosch, he develops pressure sensors for braking systems in cars. "It wasn't quite that simple," he says – Bernhard's typical understatement that gives an idea of the complexity of the task. Bosch brought him in as project manager in brake system development, where Winfried Bernhard's liaison with quality began. "We analyzed which defects a sensor has and eliminated them one by one, we used quality methods such as failure mode and impact analysis – even here, quality was a central part of my work. The new sensor should be simpler than the old one and better at the same time." It is such multiple challenges that appeal to Winfried Bernhard.

What also appeals to him is the big, wide world. In his youth, he traveled as far as he could in GDR times through all of Eastern Europe, all the way to the Black Sea. During his studies, when the Wall fell, he was drawn to Scotland for a year. He travels to Tanzania with his wife. He went to China for three years for work. In Suzhou in eastern China, near Shanghai, he is helping to build a new Bosch plant for automotive electronics and is taking over quality management at the site with 2,500 associates. "I worked a lot," says Winfried Bernhard succinctly. In China, this means, of course, also on weekends. "On Friday evening, a customer called: he had a problem with three of our products, i.e. with three out of a million. On Monday I may be on site with him. Okay, I said, and ordered pizza for the team. We had a very intense weekend. On Sunday evening I got on the plane, on Monday I showed the customer a solution. So the expectations of Asian customers were: very challenging."

After three years for Bosch in China, Winfried Bernhard is moving "closer" to his homeland again and moving to Solothurn in Switzerland, where he will head the quality and manufacturing technology divisions of a Bosch plant for power tools for six years. When the plant was relocated to Hungary, Winfried Bernhard made a cut and went on a trip around the world: with his wife and daughter, who had just graduated from high school, he traveled through Myanmar, Thailand and Cambodia; then with the camper through Australia. They celebrate New Year's Eve in Sydney, explore New Zealand, experience the cherry blossom in Japan, travel to some South Sea islands and end in Chile. Peru, Ecuador and Galapagos are catching up with a small delay. "We saw and experienced a lot, met interesting people, hiked, were together 24 hours a day, talked intensively with each other. It was a wonderful time."

Back in Germany, Winfried Bernhard changed industries: An interesting job brought him to an Upper Franconian medical technology company that manufactures, among other things, highly sensitive intracranial pressure sensors. He stayed as a quality manager for eight years and then – the new challenge tempted him – moved to an innovative start-up that developed surgical robots for minimally invasive surgery. While the development of braking systems was already indirectly about human lives for Winfried Bernhard, it was very directly involved in the medical industry with intracranial pressure sensors and surgical robots. "These were very sophisticated products and I learned a lot about quality standards once again." With this knowledge and over twenty years of experience in senior quality management, Winfried Bernhard will join GEALAN at the beginning of 2024. The construction industry ticks completely differently than the automotive and medical technology industries; nevertheless, the approach in the quality area is similar. "The standards are also very high at GEALAN and the technologies that work elsewhere also help us move forward." One example is the lean management that is implemented in GEALAN production: Every form of waste is to be avoided and processes are to be optimised in such a way that mistakes do not happen in the first place. 5S, a Japanese method of cleanliness and the systematic sorting of objects and processes, has also long been part of GEALAN's everyday life – the company is convinced that quality can only be achieved in clean, tidy workplaces. "In shop floor meetings, we talk directly to the employees: What is the current quality situation and what can each individual do to improve it?" Quality is not a one-man show. It starts with purchasing, where suppliers have to deliver good products, and applies in particular to production – in Tanna a total of 37 extrusion lines and lamination lines – where the machines have to be operated optimally in order to produce profiles of the highest quality. "But we also need very good design and very good tools, because they have a very big influence on quality. Quality optimisation also includes storage, packaging and transport, where good handling avoids damage. When we talk about a quality offensive, all employees, all areas are involved."

Focusing on what customers want played a major role for Winfried Bernhard not only in China, but also at GEALAN. Customer feedback is a central input for quality management; if it is in the form of a complaint, it is a direct order to improve. That's why the quality manager's schedule includes customer visits every month. "The personal relationship and the conversation are very important. When you know each other, it's easier to talk about topics – often about small ones before there are big ones. Winfried Bernhard will be on site to see how GEALAN partners process the window profiles and what challenges they face. "Not every customer is the same, some are highly automated, some have manufactories and build individual windows. It's important to me to listen carefully."

Countless observations of reality, analyses of complicated relationships – and then in the end there is such a simple equation: E = mc2. Energy-mass equivalence, formulated by Albert Einstein in 1905, is one of the best-known laws of nature and a fascination for the physicist Winfried Bernhard. "When details add up to the big theory and the solution looks so simple in the end – that's the beauty of it all."

The main goal of GEALAN's quality offensive is to deliver the right products in the right number in error-free quality. According to Winfried Bernhard, it is central to create an awareness of quality and diligence in management and among all employees. "We need transparency and communication – the entire team must be aware of the quality situation." In order to research where problems occur, GEALAN has introduced a complaints management system that records various errors detected by the customer via SAP. A categorization identifies major errors that are addressed with priority. "Finding out the causes of problems is the point. No error has only one reason, we have to find them all and then fix them one by one. On the other hand, there is not just one patent solution, but many steps that we have to take – this is the only way to raise quality."

"Some people say quality costs. I say: Poor quality costs. Good quality moves us forward. I get the best quality improvement when I optimize processes. An error-free process brings the better result, lower costs and higher efficiency."

In addition to the new camera systems in extrusion, GEALAN is also testing quality-enhancing innovations in logistics: RFID chips could make the picking of profiles much easier in the future. A separate RFID chip is to be attached to each profile, which will indicate exactly which system it is, in which design and color: an identity card of the profile. The employee scans the RFID tag and can immediately be sure that he has the right profile in front of him. Confusion that could happen with the naked eye, for example with very similar colors, would be excluded with this technique. The RFID reader can also use an acoustic signal to indicate that the profile you are looking for is in the immediate vicinity, making it easier to find. "Of course, our logistics employees have other good ideas that could be realized with RFID: We could optimize warehouse management because we would have a very quick overview of the real inventory, contactless." Completely picked deliveries could pass through an RFID gate for inspection, which checks again whether all products have really been packed in the right number. "I have picked myself and know how difficult it is to pick 300 glass beads. We counted in pairs, we counted three times." RFID technology could support employees very well. "Our product world is complex. With the large number of profiles that we pick, even errors in the per mille range are noticeable."

"Of course, we need technology to avoid mistakes and check quality. But the key to our quality offensive is our employees – with the right mindset and enthusiasm for what they do."

Ultimately, quality improvements are also, but not only, about avoiding errors, says Winfried Bernhard. The goal must always be to optimize complete processes so that errors do not occur in the first place and processes work better at the same time. "In our quality projects, we work with a return-of-investment approach. I am firmly convinced that good quality reduces costs, not only in the long term, but quickly." The quality data is evaluated monthly via SAP Analytics Cloud, which allows the quality situation to be analyzed very precisely. Of course, the work on quality is never finished. Because new topics are constantly emerging and because the demands of GEALAN customers are increasing – the more companies grow, the more they automate, the more they pay attention to quality.

"I like quality because it's not easy," says Winfried Bernhard. His predilection for the difficult, for the complex and complicated, is not a very common trait. To look closely at things, to see them as they really are, to break down the big picture into smaller things and to recognize connections – this analytical spirit of the physicist characterizes Winfried Bernhard's thinking – and is perhaps the ideal quality for someone who really wants to increase quality. As structured and systematic as Winfried Bernhard approaches his work, in private he sees things casually. "I'm not as planned and structured as you might expect, even on our trip around the world we didn't organize everything months in advance. There must also be room for surprises and spontaneity." Winfried Bernhard enjoys spending his free time with his family and granddaughters. Together they go cycling. This also has to do with quality, albeit on a completely different level.

Götz Gemeinhardt

25/11/2025

Latest articles

GEALAN from the inside

GEALAN from the inside

A really good tool for internal communication: GEALAN inside is anything but a bulletin board; the digital platform is a prime example of how internal company information can be bundled and prepared in a user-friendly way. GEALAN inside is packed with interesting facts and yet clear, offers umpteen functions and is easy to use. All those who work at GEALAN have their virtual meeting place – and on top of that, GEALAN inside looks chic too.

"Customers who challenge us"

"Customers who challenge us"

GEALAN has 2022 its premium system GEALAN-KONTUR®. It combines design-oriented Design language with convincing Technical Characteristics. Its development was a joint project between the system provider and two window manufacturers: Felbermayer and PaX. Robert Tänzel (45), Sales Head of Division at GEALAN, has talked to us with the two project partners. He tells of a challenging all sides Cooperation. And of other challenges he has tackled – long before he has joined GEALAN.

99 percent is not enough

99 percent is not enough

Trucks roll along highways and transport goods from A to B. A symbol of logistics. This is not a false picture, but an incomplete one. The German Logistics Association (BVL) defines logistics as the holistic planning, management, coordination, implementation and control of all internal company processes. and cross-company flows of information and goods. Sounds complex and it is. GEALAN is making its logistics more and more efficient, thus pursuing one goal: maximum delivery reliability.

Contact us, we will be happy to help you.

Do not miss any news!

I want to receive newsletter "Reference Building of the Month" and GEALAN news via E-Mail (approx. twice a month) - free of charge and terminable at any time.